Products

Contact Us

Tel: +86-577-86866707

Fax: +86-577-86866707

Mob: +86-15906484621

E-mail: kaysenflange@hotmail.com

ASME B16.48 Spectacle Blind Flange Spade, Ring Spacer

ANSI B16.48 forged spectacle blind flange class 300

Standard: ANSI B16.48

Flange type: spectacle blind Flange Raised Face

Size range: 1/2''-24''

Pressure: Class 300

Material: Stainless steel , Alloy Steel , Carbon Steel

Standard: ANSI B16.48

Flange type: Spectacle Blind Flange Raised Face type 4

Size range: 1/2"-24"

Pressure class: Class 300

Surface treatment:Anti-rust oil,transparent/yellow/black,Anti-rust paint,Zinc,Hot dipped

galvanized

Specialize:As per drawing

Material of Spectacle Blind Flange Raised Face:

Stainless Steel Material of Spectacle Blind Flange Raised Face:

ASTM A182F304,304L,304H,316,316L,316Ti,310,310S,321,321H,317,347,347H,904L

Duplex stainless steel UNS S32304,S31803,S32205.

Super Duplex stainless steel UNS S32750/S32760/S31260/S32550/S32707

Carbon Steel Material of Spectacle Blind Flange Raised Face:

ASTM A105, Q235, A350 LF2,ASTM A694 F42/F46/F52/F60/F65/F70/F80

Alloy Steel Material of Spectacle Blind Flange Raised Face:

ASTM A 182, GR F1,F5, F9, F11, F22, F91

Copper&Nickel Alloy Material of Spectacle Blind Flange Raised Face:

CU/NI 90/10, CU/NI 70/30

Nickel Alloy Material of Spectacle Blind Flange Raised Face:

Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276

Surface treatment:Anti-rust oil,transparent/yellow/black,Anti-rust paint,Zinc,Hot dipped

galvanized

Usage:Oil field, Offshore,Water system,Shipbuilding,Natural gas,Electric power, Pipe

projects,etc.

Standard: ANSI B16.48

Flange type: spectacle blind flange Raised Face

Size range: 1/2''-24''

Pressure class:Class 300

Material : Stainless steel , Alloy Steel , Carbon Steel

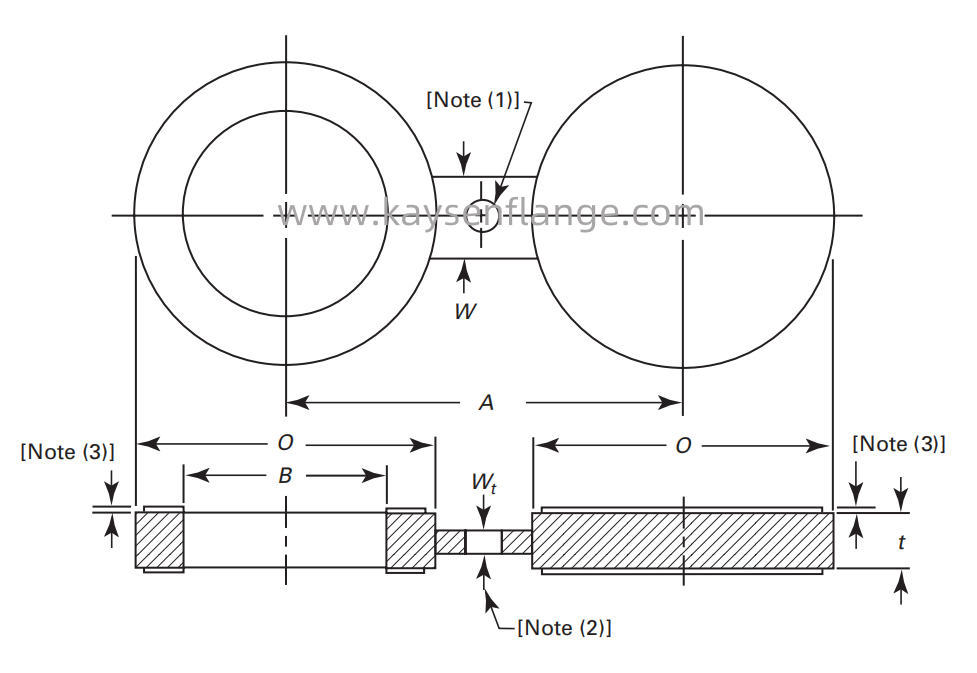

| Dimensions of Class 300 Raised Face Figure-8 Blanks | |||||

| NPS | Inside Diameter,B, mm |

Outside Diameter, O, mm |

Centerline Dimension,A, mm |

Thickness,t, mm |

Web Width,W,mm |

| 1/2 | 16 | 51 | 65 | 6.4 | 38 |

| 3/4 | 21 | 64 | 80 | 6.4 | 38 |

| 1 | 27 | 70 | 90 | 6.4 | 38 |

| 1 1/4 | 42 | 79 | 100 | 6.4 | 38 |

| 1 1/2 | 48 | 92 | 115 | 6.4 | 38 |

| 2 | 61 | 108 | 125 | 9.7 | 51 |

| 2 1/2 | 73 | 127 | 150 | 9.7 | 51 |

| 3 | 89 | 146 | 170 | 9.7 | 64 |

| 3 1/2 | 102 | 162 | 185 | 12.7 | 64 |

| 4 | 114 | 178 | 200 | 12.7 | 64 |

| 5 | 141 | 213 | 235 | 15.7 | 76 |

| 6 | 168 | 248 | 270 | 15.7 | 76 |

| 8 | 219 | 305 | 330 | 22.4 | 76 |

| 10 | 273 | 359 | 385 | 25.4 | 102 |

| 12 | 324 | 419 | 450 | 28.4 | 102 |

| 14 | 356 | 483 | 515 | 31.8 | 108 |

| 16 | 406 | 536 | 570 | 38.1 | 108 |

| 18 | 457 | 594 | 630 | 41.1 | 114 |

| 20 | 508 | 651 | 685 | 44.5 | 121 |

| 24 | 610 | 772 | 810 | 50.8 | 140 |

GENERAL NOTE:

1.Dimensions are in millimeters

2.Hole size (where required due to bolt spacing) shall be the same as the flange bolt hole and located such that it will not interfere with bolting between two flanges.