Products

Contact Us

Tel: +86-577-86866707

Fax: +86-577-86866707

Mob: +86-15906484621

E-mail: kaysenflange@hotmail.com

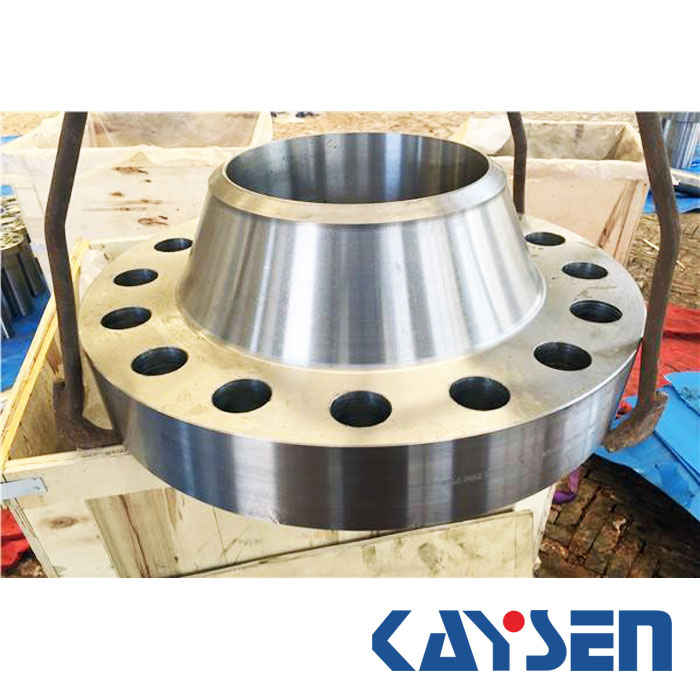

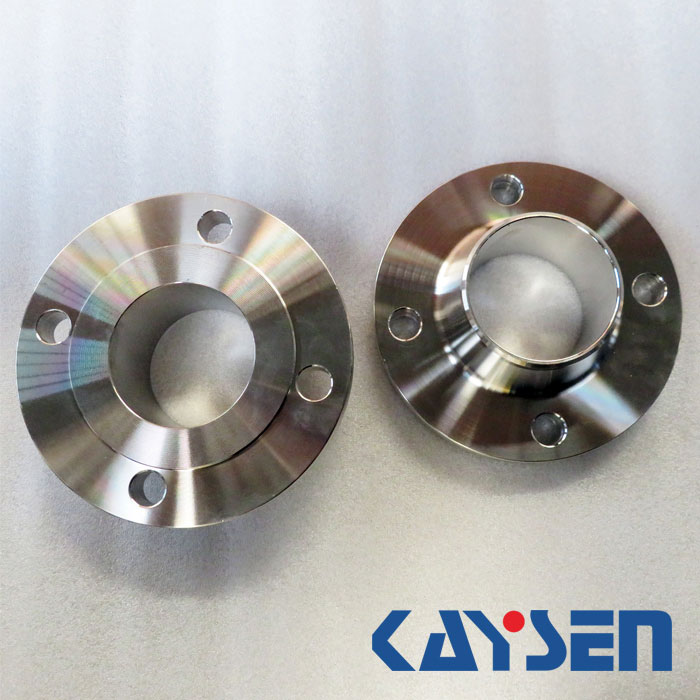

DIN Welding Neck Flange

DIN 2628 PN250 Weld Neck Flange

Standard: DIN2628

Flange type: Welding Neck Flange

Size range: DN10-DN250

Pressure: PN250

Material: Stainless steel,Alloy Steel,Carbon Steel,Copper&Nickel Alloy,Nickel Alloy,etc.

▲Standard: DIN2628

▲Flange type: Welding Neck Flange

▲Size: DN10-DN250

▲Pressure: PN250

▲Connection type: Ring type joint,Lap-joint face,Raised face,Flat face,Large male-female,Small male-female,Large tongue & groove,Small tongue & groove.

▲ Material:

1) Stainless Steel Material:

ASTM A182 F304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L

Duplex stainless steel UNS S32304,S31803,S32205.

Super Duplex stainless steel UNS S32750/S32760/S31254/S31260/S32550/S32707

2) Carbon Steel Material:

ASTM A105, A350 LF2,P235GH,P250GH,SS400,Q235,C22.8,20#,16mn.

3) Alloy Steel Material:

ASTM A 182, GR F1,F5, F9, F11, F22, F91

ASTM A694 F42/F46/F52/F60/F65/F70/F80.

4) Copper&Nickel Alloy Material:

CU/NI 90/10, CU/NI 70/30

5) Nickel Alloy Material:

Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276

▲Surface treatment: CNC Machined&Finishing, Anti-rust oil,Transparent/Yellow/Black Anti-rust paint, Hot dipped/ Electric galvanized.

▲Usage:Oil field, Offshore, Water system, Shipbuilding, Natural gas,Electric power, Pipe projects,etc.

This product Keywords:DIN 2627 FLANGE

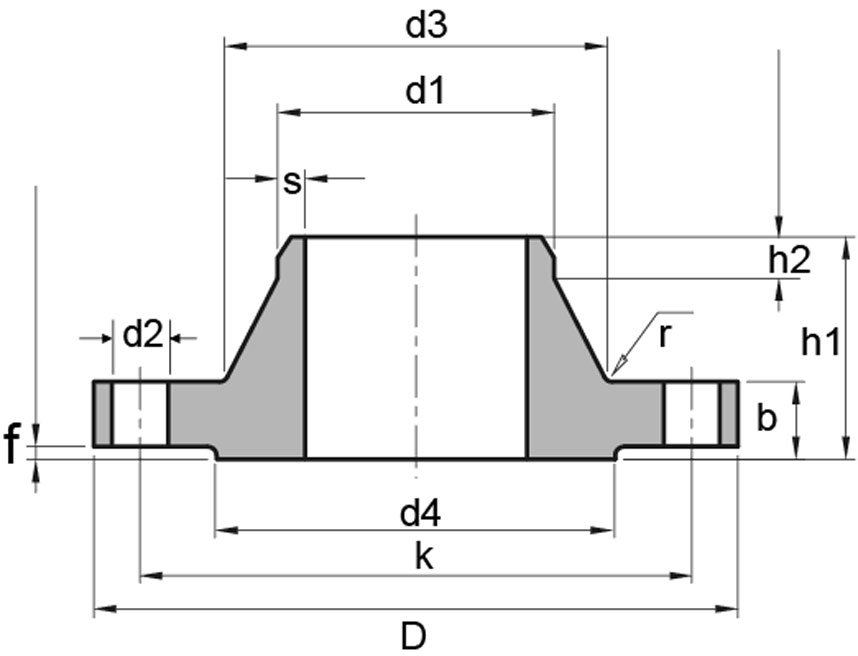

DIN 2628 PN250 Weld Neck Flange Dimensions in mm.

| Pipe | Flange | Neck | Raised face | Screws | Weight | |||||||||||

| Rated | d1 | D | b | k | strong | D3 | S | r | strong | d4 | f | No. of Holes | Thread | d2 | (7.85 Kg/dm3) | |

| DN | ISO | DIN | Each | KG/PCS | ||||||||||||

| 10 | - | 14 | 125 | 24 | 85 | 58 | 44 | 2.6 | 4 | 6 | 40 | 2 | 4 | M16 | 18 | 2.10 |

| 17.2 | - | 125 | 24 | 85 | 58 | 44 | 2.6 | 4 | 6 | 40 | 2 | 4 | M16 | 18 | 2.09 | |

| 15 | - | 20 | 130 | 26 | 90 | 60 | 48 | 2.6 | 4 | 6 | 45 | 2 | 4 | M16 | 18 | 2.48 |

| 21.3 | - | 130 | 26 | 90 | 60 | 48 | 2.6 | 4 | 6 | 45 | 2 | 4 | M16 | 18 | 2.47 | |

| 25 | - | 30 | 150 | 28 | 105 | 65 | 60 | 3.6 | 4 | 8 | 68 | 2 | 4 | M20 | 22 | 3.56 |

| 33.7 | - | 150 | 28 | 105 | 65 | 60 | 3.6 | 4 | 8 | 68 | 2 | 4 | M20 | 22 | 3.53 | |

| 40 | - | 44.5 | 185 | 34 | 135 | 80 | 84 | 5 | 6 | 10 | 88 | 3 | 4 | M24 | 26 | 6.65 |

| 48.3 | - | 185 | 34 | 135 | 80 | 84 | 5 | 6 | 10 | 88 | 3 | 4 | M24 | 26 | 6.58 | |

| 50 | - | 57 | 200 | 38 | 150 | 85 | 95 | 6.3 | 6 | 10 | 102 | 3 | 8 | M24 | 26 | 8.17 |

| 60.3 | - | 200 | 38 | 150 | 85 | 95 | 6.3 | 6 | 10 | 102 | 3 | 8 | M24 | 26 | 8.09 | |

| 65 | 76.1 | - | 230 | 42 | 180 | 95 | 124 | 8 | 6 | 12 | 122 | 3 | 8 | M24 | 26 | 12.59 |

| 80 | 101.6 | - | 255 | 46 | 200 | 102 | 136 | 11 | 8 | 12 | 138 | 3 | 8 | M27 | 30 | 16.32 |

| 100 | 127 | - | 300 | 54 | 235 | 120 | 164 | 14.2 | 8 | 14 | 162 | 3 | 8 | M30 | 33 | 27.07 |

| 125 | 152.4 | - | 340 | 60 | 275 | 140 | 200 | 16 | 8 | 16 | 188 | 3 | 12 | M30 | 33 | 38.79 |

| 150 | 177.8 | - | 390 | 68 | 320 | 160 | 240 | 17.5 | 10 | 18 | 218 | 3 | 12 | M33 | 36 | 59.05 |

| 200 | 244.5 | - | 485 | 82 | 400 | 190 | 305 | 25 | 10 | 25 | 285 | 3 | 12 | M39 | 42 | 109.45 |

| 250 | 298.5 | - | 585 | 100 | 490 | 215 | 385 | 32 | 12 | 30 | 345 | 3 | 16 | M45 | 48 | 189.94 |